Production & Processing

At Stonetech, we leverage cutting-edge technological machinery to process our marbles and other surfaces, ensuring the highest quality standards are met at every stage.

1. Block Squaring: Upon extraction from the quarry, blocks undergo immediate squaring to rectify any irregularities or chipped surfaces. This critical step ensures that our materials are primed for further processing or exportation, guaranteeing optimal quality and integrity.

2. Block Ripping and Slab Cutting: Blocks are expertly ripped and cut into precise slabs tailored to meet the unique specifications of each project. Whether it is a large-scale construction or sophisticated architectural design, our state-of-the-art machinery ensures unparalleled precision and consistency in slab dimensions.

3. Advanced Processing for Finished Products: Our commitment to excellence extends to the production of finished products. At this stage, combined with our automation and robotic production technologies our skilled engineers and craftsmen utilize advanced techniques to create cut-to-size slabs and tiles, execute intricate stone finishing, create bespoke surfaces and patterns, reinforce marble for durability, implement specialized architectural features, and fabricate finished products. Each process is executed with precision and expertise, resulting in superior quality and aesthetic appeal.

Through seamless integration of technology and craftsmanship, we strive to deliver exceptional products that exceed the expectations of our clients and elevate the standards of excellence in the industry.

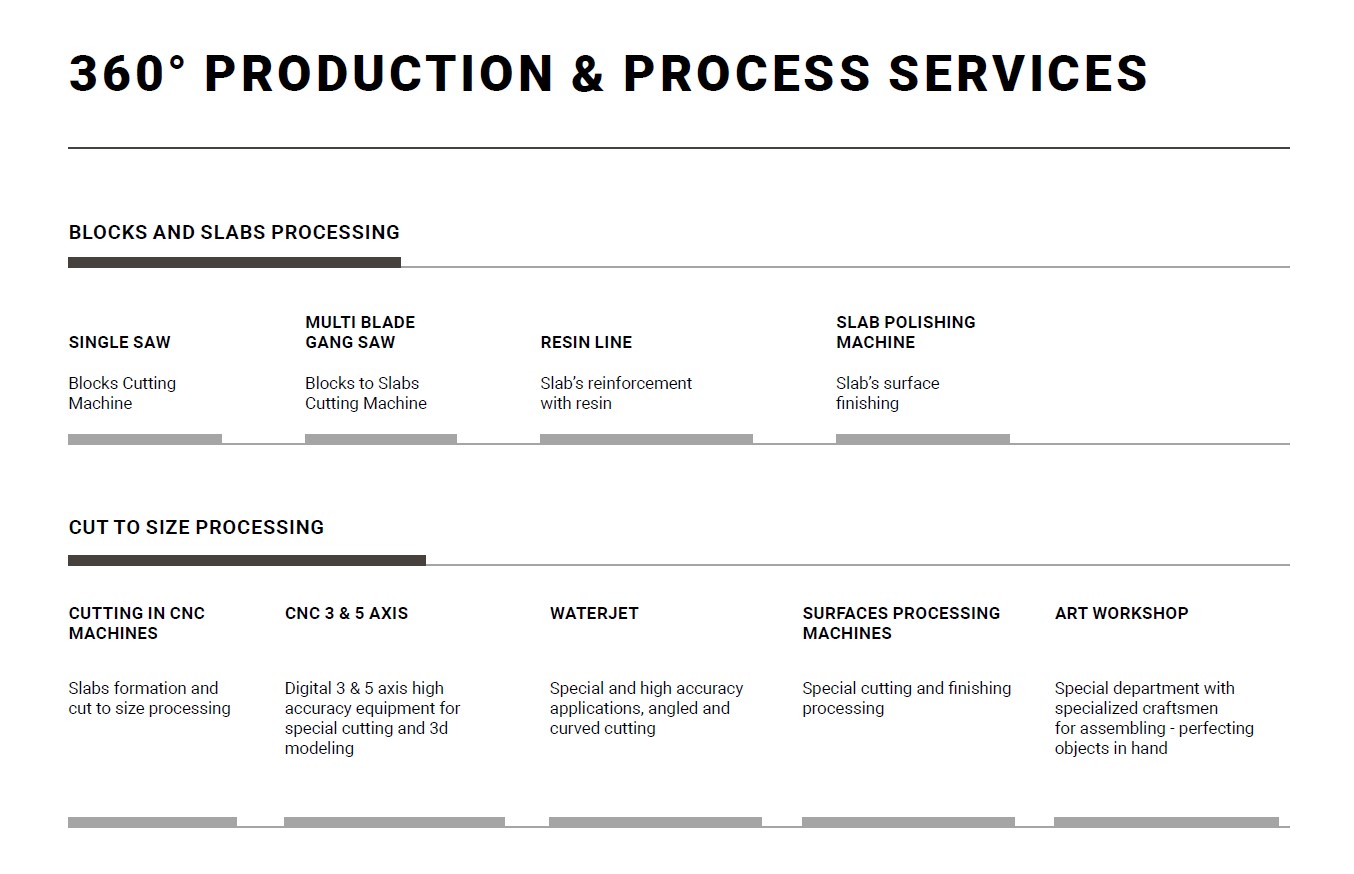

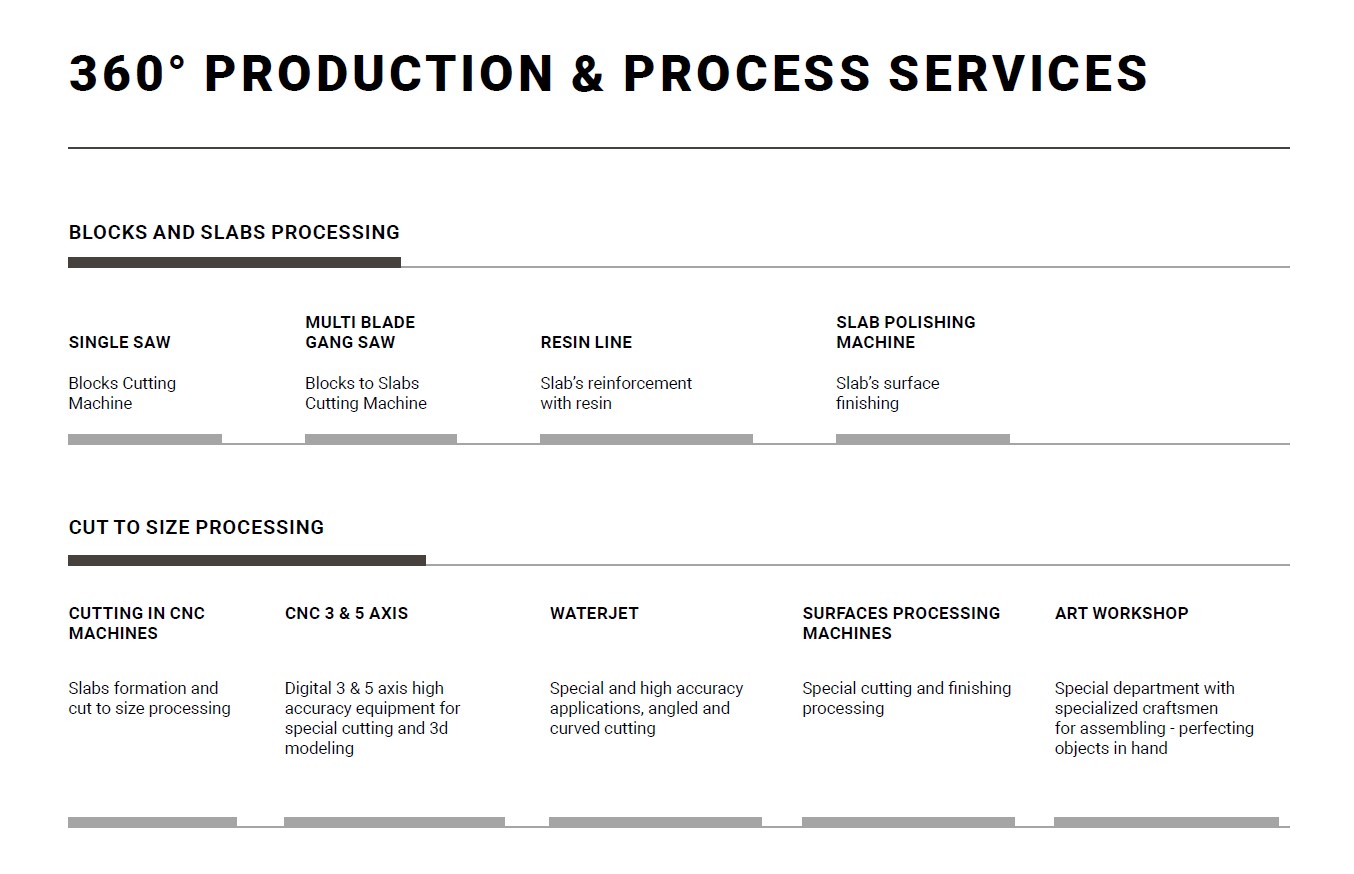

Our production capabilities are analyzed and segmented into the following key activities:

1. Block Squaring: Upon extraction from the quarry, blocks undergo immediate squaring to rectify any irregularities or chipped surfaces. This critical step ensures that our materials are primed for further processing or exportation, guaranteeing optimal quality and integrity.

2. Block Ripping and Slab Cutting: Blocks are expertly ripped and cut into precise slabs tailored to meet the unique specifications of each project. Whether it is a large-scale construction or sophisticated architectural design, our state-of-the-art machinery ensures unparalleled precision and consistency in slab dimensions.

3. Advanced Processing for Finished Products: Our commitment to excellence extends to the production of finished products. At this stage, combined with our automation and robotic production technologies our skilled engineers and craftsmen utilize advanced techniques to create cut-to-size slabs and tiles, execute intricate stone finishing, create bespoke surfaces and patterns, reinforce marble for durability, implement specialized architectural features, and fabricate finished products. Each process is executed with precision and expertise, resulting in superior quality and aesthetic appeal.

Through seamless integration of technology and craftsmanship, we strive to deliver exceptional products that exceed the expectations of our clients and elevate the standards of excellence in the industry.

.jpg)